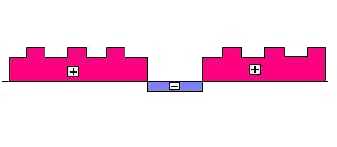

- PROCESS COMPUTER

- TREATMENT PARAMETERS

PRINTING DEVICE

(for quality control)

Main Unit

|

RECTIFIERS FOR PLATING AND ANODIZING |

AVAILABLE:

|

|

PLATING (Zinc, Nichel, Chromium, Hardchromium) |

Four types of ELCA rectifiers are available for plating |

|

|

|

TYPE N Conventional rectifier |

TYPE NR Conventional rectifier with reversing polarity |

|

|

|

TYPE PRP Pulse rectifier with periodic reversing polarity |

TYPE PRPR Pulse rectifier with periodic and continuous reversing polarity |

|

TECHNICAL FEATURES

Control:

Rectifier circuit: Main transformer: according to IEC 742 standard "Safety isolating transformers"

General switch:

Cooling:

Protections:

Voltage/current control:

For pulse rectifiers: |

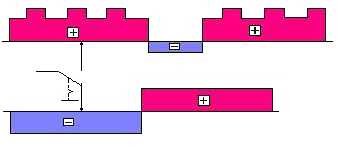

RECTIFIERS TYPE N - NR |

|

"Constant current" and "constant voltage" control (choice by means of a switch) RIPPLE

It is well known that the lower the working actual voltage in comparison with the rated voltage of the rectifier the higher the ripple value (alternate voltage superimposed on the average direct one).

If you foresee a widely changeable working voltage and if a low ripple value is requested it is advisable to equip the unit with an inductance-capacitor (L-C) smoothing filter (see optional list).

|

RECTIFIERS TYPE PRP |

|

They have the following particular features: - Positive pulses can be superimposed on the base level (adjustable between 0-50% of the base level). - Longer period (some seconds) of direct current are followed by very short (some milliseconds) polarity reversals.

Thanks to the positive pulses superimposed on the base level the deposition rate and the throwing power are increased.

|

RECTIFIERS TYPE PRPR |

|

By means of them also continuous reversing polarity (f.i. for etching) can be obtained.

|

OPTIONALS FOR ELCA RECTIFIERS |

|

|

|